Zebra ZT200 series Printers

Zebra incorporated extensive customer feedback, as well as the legacy of its Stripe® and S4M™ printers, to create the new ZT200 series printers, which feature elegant space-saving design, effortless setup, intuitive user operation, and ease of service and maintenance. Whether you are adopting barcode technology for the first time or upgrading existing printer models, the ZT200 series is the right choice for a variety of labelling applications. These innovative new printers provide many user benefits.

The ZT200 series offers a streamlined design and smaller footprint that takes up less physical space than the Stripe and S4M models. ZT200 series printers require minimal operator training and benefit from tool-less standard component maintenance and a durable design to minimise service. Your IT staff will appreciate the backwards compatibility, since it allows for new printers to be up and running with minimal downtime.

The ZT200 series uses Zebra’s Link-OS™ environment: an open platform that pairs an operating system for smart Zebra devices with powerful software apps. AirWatch® Connector allows for simplified device management.The Print Station app quickly enables tablet- and smartphone-based printing. And with Cloud Connect, the ZT200 series printer can connect to the cloud directly and securely.

The ZT200 series has been designed for ease of use, versatility and outstanding value.

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

Zebra® ZT200™ seriesZebra FS40 Fixed Industrial Scanner

Enable Performance. Inspire Potential. Experience The Difference.

Today more than ever, the increasing demands of international commerce and its global supply chain are pressuring companies to deliver more — and to do it faster. From manufacturing to logistics to the end customer, success is driven by the ability to quickly move and track the products that drive your business.

Address it all with Zebra’s FS40 Fixed Industrial Scanner designed to meet the comprehensive requirements of today’s production and delivery processes. The FS40 easily keeps pace with the fastest moving operations, enabling track-and-trace through the automatic and flawless decode of information on every part and package as it moves through production, storage and fulfilment — capturing even the most challenging barcodes. The result? Best-in-class production, warehousing, distribution and logistics processes that inspire businesses to reach their highest potential.

View ProductGeset 117 Top and Bottom Labelling System

The Geset 117 labelling system is used to label square products on the top and bottom side automatically. Depending on the type and dimension of the product, different label sizes are used. The products are fed manually or by a conveying system provided by the customer at an infeed passage on the labelling system. Care should be taken on accurate alignment of the products. It is essential that the products are forwarded separately to the applicator with a gap between each other.

When the light barrier is reached, an application trigger is tripped. Both label applicators apply then in Wipe On procedure a label onto the product. The label on top side is pushed on the product by a brush or roller. The label on bottom side is pushed on the product by the self-weight of the product. After labelling the products move on and can be removed from conveyor by the customer.

View ProductMarkoprint Integra PP RAZR

Experience Effortless High-Resolution Printing: Introducing the Integra PP RAZR with Cutting-Edge Technology. Print Up to 34mm High on Virtually Any Product Surface with Ease. Be Amazed by the Permanent Print Head’s Impressive Resolution, Lightning-Fast Speed, and Integrated Redundancy. Plus, its Compact Design Ensures Seamless Placement in Any Production Facility.

View ProductMarkoprint NonStop Printing

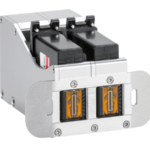

To enable continuous marking in ongoing production, our Markoprint NonStopPrinting printhead holds two alternately printing cartridges. Because the other ink cartridge is printing on the same position, each ink cartridge can be changed, cleaned, or serviced without pausing the machine.

An intelligent automatism prevents both cartridges from going empty at the same time. The first cartridge will always print two consecutive print jobs, taking turns with the second cartridge, which will only print one. This sophisticated automatism avoids both cartridges from running out at the same time. This will keep the ink from drying out in both cartridges. When the cartridge with the larger print volumes is empty, a warning will show, and the other cartridge will continue printing until it is replaced. The new cartridge will print the lower quantities to allow for you to replace the “older” cartridge. A sophisticated workflow that will boost your efficiency and productivity.

View Product