Weber’s Alpha Series Makes

It’s Mark in Product Identification

The demands for ever greater productivity within modern manufacturing facilities means that production equipment must provide the highest levels of flexibility and reliability. This requirement extends through all stages of production to the labelling and printing systems that generate the product identification, date coding and traceability information which is an essential element of any production process.

Having equipment which can cater for a diverse range of products, each with their own specific marking and labelling requirements is crucial in the drive for ongoing efficiency.

Meeting the demands of today’s production and packaging lines requires a comprehensive range of labelling and coding equipment backed by extensive applications knowledge. Weber’s latest Alpha Series provides solutions for label dispensing, thermal and inkjet printing, laser marking plus a multiple label applicator system, all of which are designed to provide maximum performance in even the harshest of production environments.

The Alpha Compact label dispenser not only boasts a new design with increased performance and higher application rates (up to 600 labels per minute) but is even simpler to operate than its field proven proven predecessors. The Alpha Compact system quickly and accurately applies pre-printed labels onto products and packaging in conjunction with various applicator units. The new integrated controller further reduces the space required for this already compact unit.

The Alpha TTD labelling solution comprises of the proven and established Alpha label dispenser and a Linx thermo transfer direct printer. Using this combination, variable information can be added to pre-printed labels immediately prior to dispensing. Print quality is high, with a resolution of up to 300 dpi on label sizes up to106 mm in width. Variable post-printing with the TTD can be placed anywhere on the label, either along or across the direction of label travel. Characterised by its simple and intuitive operation the Alpha TTD labels products and packaging quickly, reliably and economically.

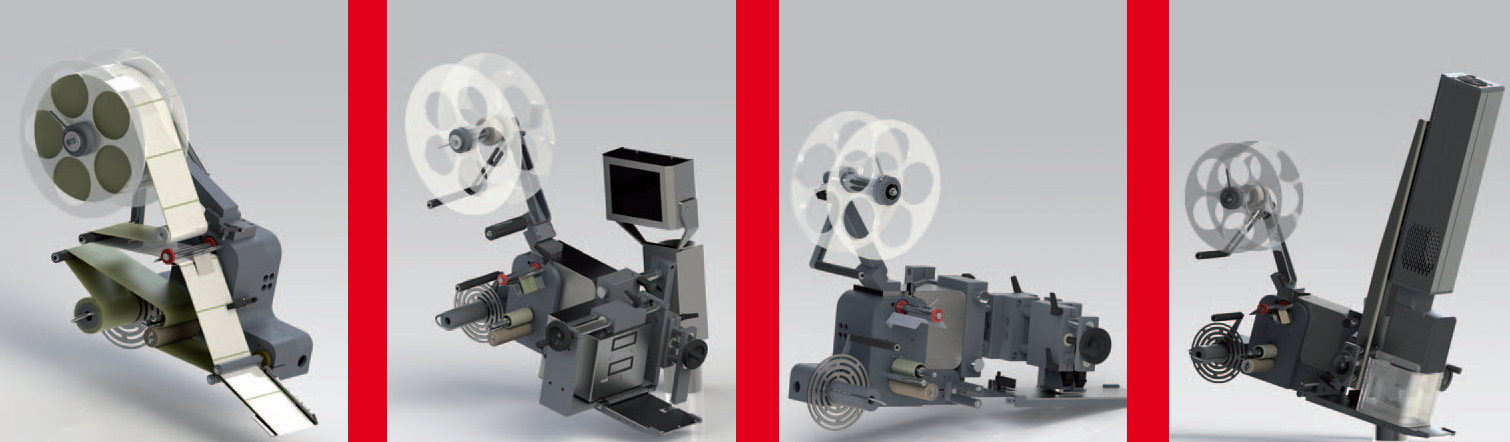

(Weber’s Alpha Series includes – left to right COMPACT, TTD, TIJ and LASER)

Weber’s Alpha TIJ reduces investment costs

There are many label dispensers on the market with the integrated option of post-printing label data, e.g. additional information such as shelf life, batch and load info, ingredients, barcodes and logos. But the conventional printing techniques available for this purpose are generally designed to be used exclusively in conjunction with an integrated labelling unit.

This is where Weber’s Alpha TIJ labelling solution differs. The printer used in the TIJ can be removed in a few simple steps then easily and conveniently installed within alternative packaging systems such as blister pack machines, cartoners, tray packers, pillow bag machines, conveyors or other similar units in the final packaging area. Depending upon application, this can translate to significantly reduced investment costs and allows multi-functionality. The Alpha TIJ comprises of a Weber Alpha Series label dispenser and a Markoprint X4 thermal inkjet printer. Using ink cartridge technology, labels with symbols of up to 50 mm in height can be printed at a resolution of up to 600 dpi. Data transmission to the print heads is 1:1. Real time printing without batch processing is also possible. A wide variety of quick drying inks and colours are available for a wide range of applications on diverse label surfaces.

Alpha Quadro the right label at the right time

The new Alpha Quadro label dispenser opens up new horizons when labelling products or packaging. This system’s special feature allows several different label rolls to be processed simultaneously. The ingenious Alpha Quadro guarantees high labelling performance and application accuracy, combined with high processing speeds.

(Weber’s ingenious multiple label Quadro system)

This innovative system addresses the growing market demands for labelling multiple products through a single line. Up to four different labels can be kept ready for automatic application to different products, in a variety of sequences and combinations. The Alpha Quadro’s special belt applicator compensates for variations in product position

Integrated product height detection allows labels to be applied at a specific position relative to the size of the product. The Alpha Quadro can also be fitted with a number of well-known standard applicators such as blow or tamp-blow units.

Cost-effective and reliable marking with the Alpha Laser

Weber’s laser labelling solution comprises an Alpha label dispenser and a Solaris CO2 laser. The Alpha Laser writes variable additional information such as best before dates, graphics or logistics data on pre-printed labels immediately prior to application.

The Alpha Laser provides virtually maintenance free, reliable and cost effective marking in high duty cycle and harsh environments. The laser can be used to write information such as batch numbers or dates etc. anywhere on the label, either along or across the direction of travel. The laser can create black text and graphics on laser-activated labels which have a special finishing coat and laser marking is smear and scratch resistant. The laser can also be used on paper, foil or laminated materials.

The new Alpha range provides the solution to a host of labelling and marking applications with the added benefit of the quality and reliability associated with the Weber brand.

For more information please contact:-

Mr Patrick Hughes

Weber Packaging Solutions

Kilcannon Industrial Estate,

Old Dublin Road,

Enniscorthy,

Co. Wexford

Y21 E281

Ireland

Telephone – +35353 9233778

E-Mail – sales@weberireland.com

Web – https://www.webermarking.ie/