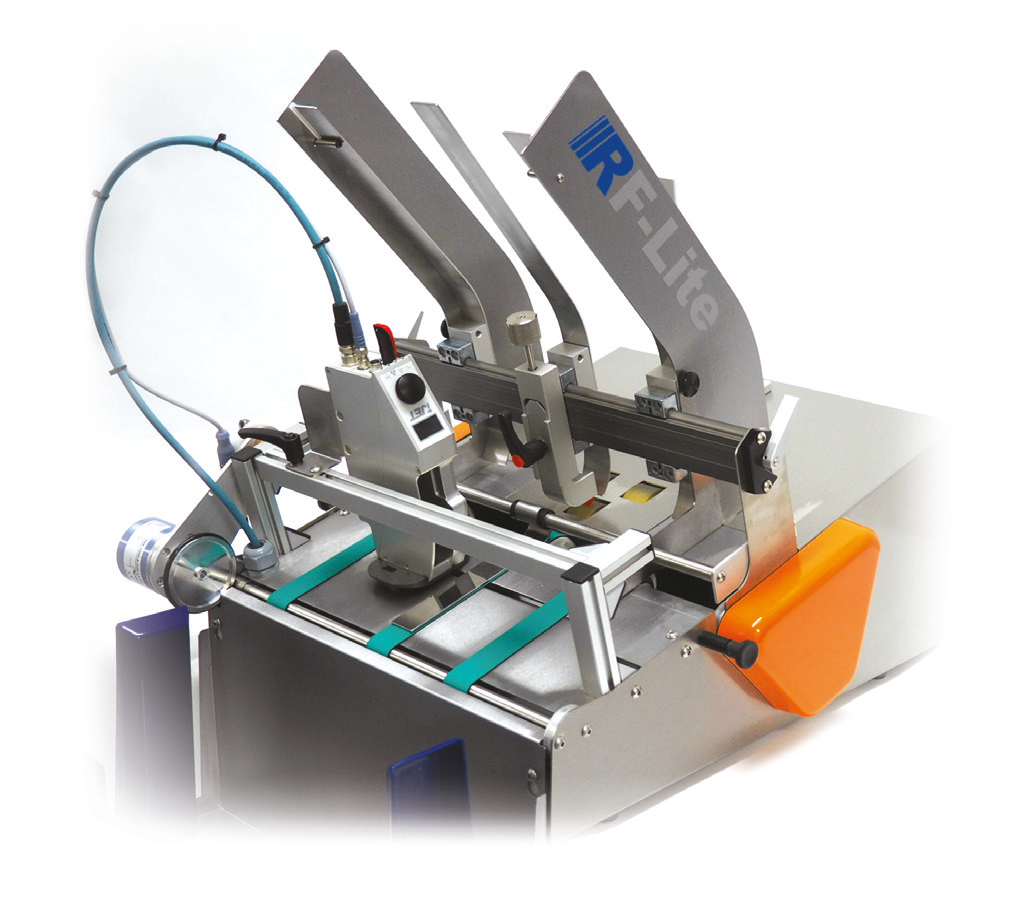

RF-Lite

Low-cost offline coding system; ideal for companies looking to automate their date marking process for the first time.

The RF-Lite is a simple, low-cost offline coding system; ideal for companies looking to automate their date marking process for the first time. It also suits larger operators who are looking to install dedicated marking systems on multiple production lines.

RIGHT CODE

Fitted with clean, thermal inkjet technology, the RF-Lite is ideal for printing

clear, concise date and batch codes onto sleeves and cartons.

RIGHT PLACE

The RF-Lite can consistently print codes onto all shapes and sizes of sleeve ranging

from 30 x 70mm to 300 x 200mm. It only takes a few seconds to swap between sizes.

RIGHT COST

With its comparatively low upfront cost, the RF-Lite is an ideal entry-level solution for companies wanting to automate their

offline date coding.

“This compact unithas dramatically reduced

the time taken to codeour cartons.”

OTHER BENEFITS

• It’s easy to set up and adjust; no training needed.

• The RF-Lite’s tiny 500 x 500mm footprint means that it can be easily squeezed into tight spaces

• We offer a money-back guarantee if the system does not meet the customers needs and expectations*

• Under our one-year warranty we can replace a broken down RF-Lite unit within 24 hours*

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

Rf-LiteMarkoprint Shutter Printhead HP

Inkjet nozzles can clog and dry up in a dusty printing environment, which is typical in wood-processing enterprises and other sectors. This results in poorly printed images. Our Markoprint Shutter Printhead HP prevents dust from entering the ink cartridge or gathering on the nozzles. During a production halt, the printhead automatically retracts the cartridge and shuts the open nozzle plate. After being paused for even several days, it is instantly ready to print again.

View ProductMarkoprint Integra PP RAZR

Experience Effortless High-Resolution Printing: Introducing the Integra PP RAZR with Cutting-Edge Technology. Print Up to 34mm High on Virtually Any Product Surface with Ease. Be Amazed by the Permanent Print Head’s Impressive Resolution, Lightning-Fast Speed, and Integrated Redundancy. Plus, its Compact Design Ensures Seamless Placement in Any Production Facility.

View ProductMarkoprint Integra PP 108

The Markoprint Integra PP108 is the first inkjet printer with SEIKO printing technology and a circulating ink system. It features a POZIFLOW circulating ink system which prevents the accumulation of air in the nozzles and ensures a permanent, clean print image without missing print due to blocked nozzles. The system’s ink tank can be installed above, below, or at the same height as the print head without any problems. The new SEIKO printhead has a print height of 108 mm and achieves a remarkable speed of up to 150 meters per minute with a high resolution of 360 dpi.

Suited to Dual Colour Printing Applications such as Hazard Labelling, Dual Colour overprinting and Direct Printing Applications to corrugate, and web printing applications, the PP108 is the latest high end, economical Inkjet System using the latest Drop on Demand Printing Technology.

View ProductMarkoprint Integra Ultimate

The innovative Integra Ultimate thermal inkjet printer not only provides IP65 protection against dust and moisture, but it also closes and cleans the nozzle plate at each pause. This system ensures that the printing is always clean, with faultless results even after extended breaks. As a result, the ink cartridges’ open times are multiplied many times. Two HP Class thermal inkjet ink cartridges can be used with the print head. As a result, the system produces beautiful prints with a maximum height of 25 mm.

View Product