Tamper Evident

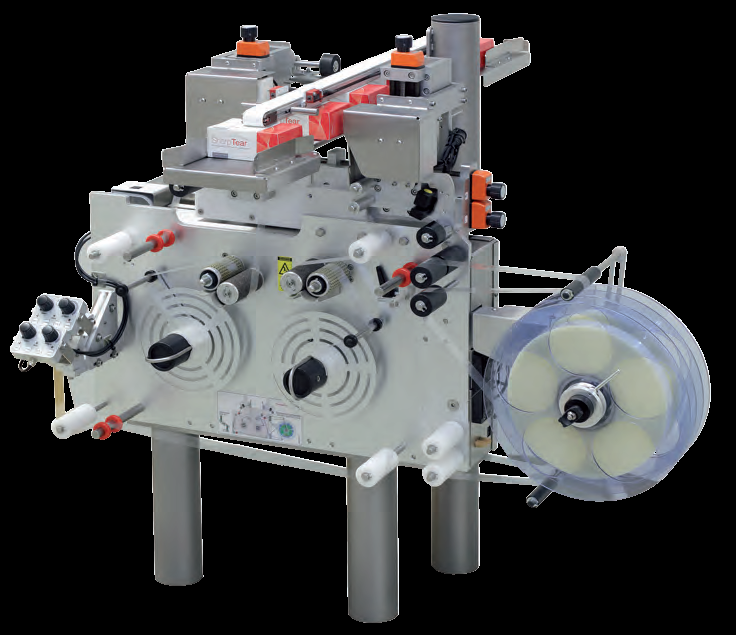

Compact label dispenser for protection against manipulation of pharmaceutical packaging.

The EU Directive 2011/62/EU promulgated in 2011 introduced legal framework requirements for a pan-European safety system for prevention of counterfeit medicines. A central component, which is also addressed in the pharmaceutical law, is a clear and secure marking system for database-backed traceability and tamper-proof sealing of all packaging. Bluhm System can offer a compact, efficient and reliable solution to this requirement. A compact labelling unit is integrated into existing data matrix stations or weighing systems. Self-adhesive label seals are applied on both sides of the flap openings of pharmaceutical packing. Perforation on the labels will expose manipulation by destruction of the labels. Depending on the packaging plant, labels are either dispensed after weighing or after an inkjet printer – e.g. the Markoprint series – has printed a sequential datamatrix code onto each package.

Following this, code and seal checking by a camera system is recommended. The package will be rejected if the marking is wrong or if a seal is applied incorrectly. Only OK products will leave the plant.

Special Features

- Sealing labelling for protection against counterfeits

- Two-sided corner labelling of folding boxes

- Highly compact design to allow integration into existing plant

- Output clocking up to 300 items per minute

- Stepper motor driven applicator

- Short set-up times when switching to other product formats

- Processing of transparent, perforated labels

- Speed-independent labelling via Tamp-Wipe-On method

- Dual label roll unwinding

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

Tamper Evident WeberX1Jet HP Premium MK2

The innovative Markoprint X1JET HP inkjet printer codes absorbent and semi-absorbent surfaces quickly, accurately and reliably. It is designed for a different range of applications in the food and beverage industry as well as the chemical and pharmaceutical industry. The controller and printer are combined in one single unit, making the system extremely compact.

View ProductGeset 141 Semi Automatic Label Dispenser

The Geset 141 semi-automatic all-round labelling system is used for labelling small tins, bottles, jars etc. This solution was developed especially for companies requiring flexible labelling of small batches. Classical applications include the pharmaceutical and cosmetics industry and the food and beverage sector.

View Product

Markoprint Integra Vivid

Unleash the Power of Modern Touch Operating Technology and an Innovative Swipe User Interface. Say Goodbye to Complicated Print Jobs and Say Hello to Effortless Operation of X1JET and PP Class Printing Systems. With the Freedom to Position the 7” High-Resolution HMI Color Display Anywhere You Choose, Prepare to Be Awed by the Ultimate Printing Flexibility and Innovation. Upgrade to integra Vivid Today and Embrace a New Era of Printing Excellence.

View ProductMarkoprint Shutter Printhead HP

Inkjet nozzles can clog and dry up in a dusty printing environment, which is typical in wood-processing enterprises and other sectors. This results in poorly printed images. Our Markoprint Shutter Printhead HP prevents dust from entering the ink cartridge or gathering on the nozzles. During a production halt, the printhead automatically retracts the cartridge and shuts the open nozzle plate. After being paused for even several days, it is instantly ready to print again.

View Product