ZEBRA ZT400 Series Printers

ZT400 printers feature USB, Serial, Ethernet and Bluetooth® connectivity along with expanded RFID capabilities. Plus, with Zebra’s Link-OS® environment, an innovative operating system, your customer can easily integrate, manage and maintain these printers from anywhere in the world.

Zebra’s ZT400 Series Printers—Designed to Grow with Evolving Needs

Keep your customers’ mission-critical operations running efficiently with the ZT400 Series printers. Constructed with an all-metal frame and bi-fold door, ZT400 Series printers deliver advancements in print speed, registration and connectivity as well as additional advanced features.

ZT400 printers feature USB, Serial, Ethernet and Bluetooth® connectivity along with expanded RFID capabilities. Plus, with Zebra’s Link-OS® environment, an innovative operating system, your customer can easily integrate, manage and maintain these printers from anywhere in the world.

The primary markets for the ZT400 Series Industrial Printers are:

- Manufacturing

- Transportation & Logistics

- Retail

- Healthcare

Key applications include:

- Asset Management

- Cross Docking

- Inventory Management

- Lab Sample Tracking

- Receiving/Shipping

- Reverse Logistics

- Work-in-Process Tracking

- Compliance Labeling

- Information Labels

- Medical Record Labeling

- Order Labeling

- Prescription Labeling

- Quality Control

Key Features:

- Application flexibility

Expand printing readiness through an exceptional range of media capabilities and media delivery options. - Effortless to integrate

USB host port enables simple printer configuration by easily transferring data from a USB flash drive via mirroring and expanding mapped-drive memory capabilities. - Easy to operate

Resolve printer errors quickly, access how-to videos and product support through Near Field Communication, and easily see inside the printer even in poorly lit environments. - Simple to manage

Manage and maintain printers from any location with Link-OS environment, interact with the Cloud and use Profile Manager to edit and manage one printer or all printers anywhere in the world. - Engineered to meet current and future business needs

Building on the ZM Series’ proven reputation for reliability, the ZT400 Series delivers advancements in print speed, connectivity options, and management and support tools. Increased processing power and user memory, along with an open architecture, allow these printers to advance with technology. End-user-installable media handling options empower customers to customize the printer to match their needs—both now and in the future. - Designed to deliver ease of integration, operation and management

Dynamic QR codes for “on-demand,” web-based support help users resolve printer errors quickly. The lighted and color-coded, side-loading supplies paths facilitate simple installation of media and ribbon and the tool-less print head and platen roller replacement keeps operations running. Zebra’s Link-OS environment delivers enhanced capabilities for monitoring, managing and maintaining ZT Series printers from any location. - Application flexibility

Standard USB, Serial, Ethernet and Bluetooth connectivity options—as well as two open media slots—allow users to utilize non-standard connectivity options (Parallel, Zigbee, etc.), design failover connections and provide for future protocols. End user installable media handling options allow users to customize the printer to match current and future business needs.

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

Industrial_Printer_Positioning_GuideEMEA_ZT400_DataSheet_GB_HR

EMEA_Zebra_ZT400_Comparison_Guide_EN_04_14_LR

Markoprint NonStop Printing

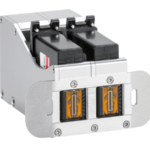

To enable continuous marking in ongoing production, our Markoprint NonStopPrinting printhead holds two alternately printing cartridges. Because the other ink cartridge is printing on the same position, each ink cartridge can be changed, cleaned, or serviced without pausing the machine.

An intelligent automatism prevents both cartridges from going empty at the same time. The first cartridge will always print two consecutive print jobs, taking turns with the second cartridge, which will only print one. This sophisticated automatism avoids both cartridges from running out at the same time. This will keep the ink from drying out in both cartridges. When the cartridge with the larger print volumes is empty, a warning will show, and the other cartridge will continue printing until it is replaced. The new cartridge will print the lower quantities to allow for you to replace the “older” cartridge. A sophisticated workflow that will boost your efficiency and productivity.

View ProductMarkoprint Integra PP 108

The Markoprint Integra PP108 is the first inkjet printer with SEIKO printing technology and a circulating ink system. It features a POZIFLOW circulating ink system which prevents the accumulation of air in the nozzles and ensures a permanent, clean print image without missing print due to blocked nozzles. The system’s ink tank can be installed above, below, or at the same height as the print head without any problems. The new SEIKO printhead has a print height of 108 mm and achieves a remarkable speed of up to 150 meters per minute with a high resolution of 360 dpi.

Suited to Dual Colour Printing Applications such as Hazard Labelling, Dual Colour overprinting and Direct Printing Applications to corrugate, and web printing applications, the PP108 is the latest high end, economical Inkjet System using the latest Drop on Demand Printing Technology.

View ProductGeset 112 Bottom Labelling System

The Geset 112 labelling system is used to label square products on the bottom side automatically. Depending on the type and dimension of the product, different label sizes are used. The products are fed manually or by a conveying system provided by the customer at an infeed passage on the labelling system. Care should be taken on accurate alignment of the products. It is essential that the products are forwarded separately to the applicator with a gap between each other.

When the light barrier is reached, an application trigger is tripped. The label applicator applies then in Wipe On procedure a label onto the product. The label on bottom side is pushed on the product by the self-weight of the product. After labelling the products move on and can be removed from conveyor by the customer.

View ProductMarkoprint Shutter Printhead HP

Inkjet nozzles can clog and dry up in a dusty printing environment, which is typical in wood-processing enterprises and other sectors. This results in poorly printed images. Our Markoprint Shutter Printhead HP prevents dust from entering the ink cartridge or gathering on the nozzles. During a production halt, the printhead automatically retracts the cartridge and shuts the open nozzle plate. After being paused for even several days, it is instantly ready to print again.

View Product