Zebra ZT510 Industrial Printer

ZEBRA ZT510 – NEXT-GENERATION PRINTING THAT IS BUDGET-FRIENDLY

Designed to strike the ideal balance between performance and value, the Zebra ZT510 includes the core features you need in an industrial printer at a cost-effective price point.

ZEBRA ZT510 – NEXT-GENERATION PRINTING THAT IS BUDGET-FRIENDLY

Designed to strike the ideal balance between performance and value, Zebra’s ZT510 industrial printer includes the core features users need at a budget-friendly price point

ZEBRA ZT510 – PERFORMANCE AND VALUE

Designed to strike the ideal balance between performance and value, the Zebra ZT510 includes the core features you need in an industrial printer at a cost-effective price point.

ZEBRA ZT510 – EXCEPTIONAL PERFORMANCE IN THE HARSHEST CONDITIONS

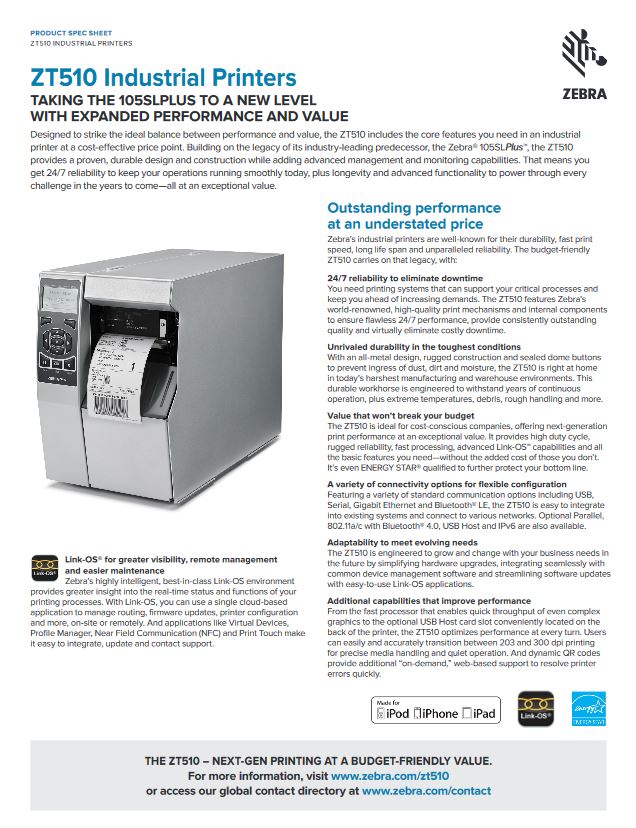

Boost your productivity with printers that just won’t quit. The Zebra ZT510 builds on the legacy of its industry-leading predecessor, the 105SLPlus. Durable steel structural components can withstand years of abuse in extreme temperatures, dust, debris and other challenging industrial conditions, and meticulously engineered printing mechanisms provide 24/7 reliability to meet your high-volume production needs.

ZEBRA ZT510 – OPERATIONAL VISIBILITY, REMOTE MANAGEMENT AND FUTURE-READY ADAPTABILITY

Zebra’s cloud-accessible Link-OS software platform and managed services offerings give you total visibility and control over your printing systems, whether you’re onsite or across the globe. Plus, with two available communication slots, field installable media-handling options and optional USB Host for plug-and-play integration, it’s easy to stay ahead of your evolving business and technology needs, whatever they may be.

ZEBRA ZT510 – A VALUE THAT WON’T BREAK YOUR BUDGET

For cost-conscious decision makers, the ZT510 offers next-generation print performance at an exceptional value. It provides high-duty cycle, rugged reliability, fast processing, advanced Link-OS capabilities and all the basic features you need — without the added cost of those you don’t.

Key Applications:

- Asset Management

- Work-in-Process Tracking

- Packaging and Labeling

- Receiving/Shipping

- Cross Docking

- Compliance Labeling

| PRINT WIDTH 4.09″ / 104 mmMAXIMUM PRINT SPEED 12 ips / 305 mm per second

COMMUNICATION METHODS |

PRINT RESOLUTION 203 dpi / 8 dots per millimeter 300 dpi / 12 dots per millimeter (Optional)CONSTRUCTION All metal |

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

zt510-specification-sheet-a4-en-apprint-head-options-guide-en-us

ZT510_Comparison_Guide_A4

DURAPRINT – Wax resin

DURAPRINT is a very versatile, multi-purpose wax-resin ribbon.

It provides a higher level of resistances compared to standard wax ribbons and

prints small characters and barcodes with a high level of quality.

Markoprint Integra PP 108

The Markoprint Integra PP108 is the first inkjet printer with SEIKO printing technology and a circulating ink system. It features a POZIFLOW circulating ink system which prevents the accumulation of air in the nozzles and ensures a permanent, clean print image without missing print due to blocked nozzles. The system’s ink tank can be installed above, below, or at the same height as the print head without any problems. The new SEIKO printhead has a print height of 108 mm and achieves a remarkable speed of up to 150 meters per minute with a high resolution of 360 dpi.

Suited to Dual Colour Printing Applications such as Hazard Labelling, Dual Colour overprinting and Direct Printing Applications to corrugate, and web printing applications, the PP108 is the latest high end, economical Inkjet System using the latest Drop on Demand Printing Technology.

View ProductMarkoprint Integra PP RAZR

Experience Effortless High-Resolution Printing: Introducing the Integra PP RAZR with Cutting-Edge Technology. Print Up to 34mm High on Virtually Any Product Surface with Ease. Be Amazed by the Permanent Print Head’s Impressive Resolution, Lightning-Fast Speed, and Integrated Redundancy. Plus, its Compact Design Ensures Seamless Placement in Any Production Facility.

View ProductEASYMARK – Standard Wax

EASYMARK is the standard Weber wax ribbon which delivers consistent print

quality on any kind of paper label materials. It prints high density legible

barcodes and traceability data for short life labeling needs.