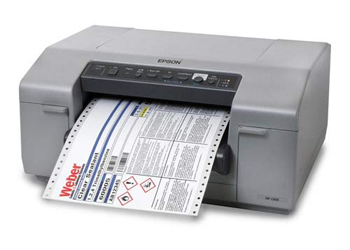

Epson ColourWorks™ GP-C831 Inkjet Colour Label Printer

Epson’s ColourWorks C831 breakthrough industrial-strength inkjet label printer is ideal for GHS large format drum and chemical labels. This wide-web printer uses pin-feed labels for extended accuracy.

Features include:

• Industrial-strength MicroPiezo® inkjet printer with tractor feeder

• First inkjet solution that has been BS5609 certified

• Printable area up to 8.0″ x 22″

• Reliability up to 1.2 million labels

• Low TCO versus colour lasers

• Fast print speeds of up to 16.5 pages per minute

Colour labels are the new standard

Epson’s ColourWorks C831 breakthrough industrial-strength inkjet label printer is ideal for GHS large format drum and chemical labels. It combines all the benefits of a rugged colour inkjet printer with the accuracy of an 8-pin tractor feeder and is the first inkjet solution that has been BS5609 certified.

It features print speeds up 16.5 pages/minute, printable areas up to 8″ x 22″, precise label feeding to reduce jamming and high-density barcode printing, all at a lower cost than colour thermal transfer or colour laser printers.

Superior ink quality and durability

Since GHS label requirements like dye-based inks, Epson’s world-renowned durable pigment-based inks firmly bind to media fibers, delivering outstanding stability and resistance to chemicals, water, fading and smudges. And the ColourWorks C831, with its durable inks, is certified to print on BS56091 approved labels, in addition to a wide variety of continuous paper and labels.

Exceptional reliability

Designed for commercial environments, the ColourWorks C831 is built to last. It is dust and water resistant, can withstand weights up to 44 lbs on its top and is virtually maintenance free with a total print volume of up to 1.2 million labels. And the print head is designed to be permanent, improving reliability and avoiding the need for frequent head replacement as with some competitive printers.

Easy to use and maintain

The ColourWorks C831 features easy access to all functions including ink replacement, an intuitive control panel, auto paper loading and more. And with its automatic paper release, paper jams are handled in no time. All of these features add up to increased productivity and reduced downtime to keep your business running.

Backed by the leader

The ColourWorks C831 wide colour label printer delivers the quality and reliability that Epson printers are known for and is backed by Epson’s industry-leading service and support programs.

GHS Labelling Software

If you are a medium to large company that manufactures or distributes multiple chemicals or formulations, you should look into Weber’s new GHS Labelling Software powered by Matrix. Whether you are using one PC or an entire network of computers in multiple locations, this system can keep your labelling operation organised, compliant and running smoothly.

Using one SQL database, fewer formats are needed. All the information is stored in one location making it easier to update. And the Weber GHS Labelling Software has a very tight audit trail so all user activities are date and time stamped for accountability.

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

ColorWorks-C831-DatasheetGeset 125 Horizontal Labelling System

The Geset 125 labelling system is used to label cylindrical products automatically. Depending on the type and dimension of the product, different label sizes are used. The products are fed manually or by a conveying system provided by the customer at an infeed passage of the labelling system. Care should be taken on accurate alignment of the products between the two freely mounted rollers of the roll conveyor. The side guide’s position the products flush with the outside edge of the roll conveyor.

The roll conveyor feeds the products to the labeller. There the label is applied with the part running forward onto the product and it is pushed by rotation and the back pressure of the wrapping unit onto the product. The back pressure of the wrapping unit (the speed of the wrapping unit is twice as fast as the speed of the base conveyor) enables the product in rotation. The roll conveyor forwards the finished labelled products to the outfeed. Here the products are removed manually or by the customer’s conveying system.

View ProductMarkoprint Integra One

Labeling systems are not always easy to integrate into preexisting production lines. The Markoprint Integra One can be easily integrated into production processes thanks to its compact dimensions of 186 x 86 x 98 mm. The printing system has a display for data entry as well as system settings modification and verification. This information can also be viewed from mobile devices if the WLAN version is selected.

Inkjet printers should be properly protected if they are subjected to harsh manufacturing circumstances. In addition, the Markoprint integra One ip has an IP 65 protection rating. As a result, it’s ideal for use in the food industry.

View ProductGeset 111 Top Labelling System

The Geset 111 labelling system is used to label square products on the top side automatically. Depending on the type and dimension of the product, different label sizes are used. The products are fed manually or by a conveying system provided by the customer at an infeed passage on the labelling system. Care should be taken on accurate alignment of the products. It is essential that the products are forwarded separately to the applicator with a gap between each other.

When the barrier is reached, an application trigger is tripped. The label applicator applies a label on the product in Wipe On procedure. The label on the top side is pushed on to the product by a brush or roller. After labelling, the products move on and can be removed from the conveyor by the customer.

View ProductZebra FS40 Fixed Industrial Scanner

Enable Performance. Inspire Potential. Experience The Difference.

Today more than ever, the increasing demands of international commerce and its global supply chain are pressuring companies to deliver more — and to do it faster. From manufacturing to logistics to the end customer, success is driven by the ability to quickly move and track the products that drive your business.

Address it all with Zebra’s FS40 Fixed Industrial Scanner designed to meet the comprehensive requirements of today’s production and delivery processes. The FS40 easily keeps pace with the fastest moving operations, enabling track-and-trace through the automatic and flawless decode of information on every part and package as it moves through production, storage and fulfilment — capturing even the most challenging barcodes. The result? Best-in-class production, warehousing, distribution and logistics processes that inspire businesses to reach their highest potential.

View Product