iJet

The Markoprint iJET high-speed control system is small, compact and with many possibilities for interlinking. Special features: Unlike other coders, the entire control technology has now been incorporated in the print module for the first time. In this way, iJET creates novel highlights in terms of integration and flexibility.

The control system with Hewlett-Packard printing technology prints up to 12.5 mm high on primary and secondary packaging – accurately and blindingly fast. Writing speeds of up to 300 meters per minute can be achieved, depending on print resolution.

iLogic – userfriendly interface

Another innovation: system control through “iLOGIC”. This offers a very user friendly man / machine interface. Input is intuitive via a combination of high-resolution display and iLOGIC operator guidance. The selection of printable text and setting up system parameters is thus very simple – setting new standards. Upward extraction of the empty cartridge is just as simple, requiring a single hand movement, and the new one is inserted with one click.

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

Inkjet Coding Overview BrochureMarkoprint NonStop Printing

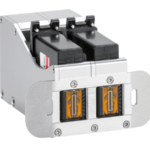

To enable continuous marking in ongoing production, our Markoprint NonStopPrinting printhead holds two alternately printing cartridges. Because the other ink cartridge is printing on the same position, each ink cartridge can be changed, cleaned, or serviced without pausing the machine.

An intelligent automatism prevents both cartridges from going empty at the same time. The first cartridge will always print two consecutive print jobs, taking turns with the second cartridge, which will only print one. This sophisticated automatism avoids both cartridges from running out at the same time. This will keep the ink from drying out in both cartridges. When the cartridge with the larger print volumes is empty, a warning will show, and the other cartridge will continue printing until it is replaced. The new cartridge will print the lower quantities to allow for you to replace the “older” cartridge. A sophisticated workflow that will boost your efficiency and productivity.

View ProductGeset 111 Top Labelling System

The Geset 111 labelling system is used to label square products on the top side automatically. Depending on the type and dimension of the product, different label sizes are used. The products are fed manually or by a conveying system provided by the customer at an infeed passage on the labelling system. Care should be taken on accurate alignment of the products. It is essential that the products are forwarded separately to the applicator with a gap between each other.

When the barrier is reached, an application trigger is tripped. The label applicator applies a label on the product in Wipe On procedure. The label on the top side is pushed on to the product by a brush or roller. After labelling, the products move on and can be removed from the conveyor by the customer.

View ProductGeset 141 Semi Automatic Label Dispenser

The Geset 141 semi-automatic all-round labelling system is used for labelling small tins, bottles, jars etc. This solution was developed especially for companies requiring flexible labelling of small batches. Classical applications include the pharmaceutical and cosmetics industry and the food and beverage sector.

View Product

PLUSMARK – Premium Wax

PLUSMARK is the high performance wax ribbon from Weber. It offers all

the benefits of a general purpose wax ribbon with an improved print durability

and a capability to print on synthetic label materials.