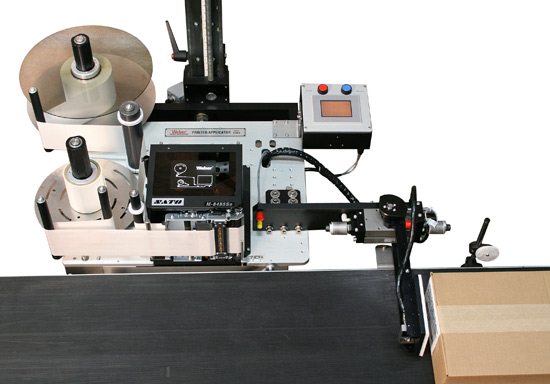

Model 5300 Series Swing-Tamp Label Printer-Applicator

This Weber exclusive provides high-resolution printing and high-speed operation combined with the swing-tamp method of label application that affixes labels to the leading or trailing side of a product.

- Choose from a wide range of 203, 300 and 600 dpi print engines

- Capable of handling print speeds up to 16 ips

- Numerous I/O’s ease interfacing with external devices

- Monitor operation via a web browser

- Available with RFID capability

Model 5300 Series Swing Tamp Label Printer-Applicator

Weber’s Model 5300 swing-tamp system is redefining the meaning of versatility in the printing and application of pressure-sensitive labels to the leading or trailing side of a product. This is the best way to add a label to your product front or back while moving along your production line.

In addition to offering a broad selection of high-quality print engines that feature various print resolutions and label dispensing rates, this Model 5300 system is available with optional RFID print-encode engines.

Standard direct and thermal-transfer print engines from manufacturers Zebra, SATO and Datamax produce text, bar codes and graphic images at 203, 300 or 600 dpi. The Zebra-based RFID models combine these printing capabilities with the encoding and verification of RFID inlays to meet EPC Gen 2 protocols.

Special Features & Options

The Model 5300 swing tamp system includes a number of noteworthy features that add to the operational versatility of this printer-applicator.

The Model 5300 swing tamp system includes a number of noteworthy features that add to the operational versatility of this printer-applicator.

• Swing tamp application: This method of label placement is used to apply a label to the front or back of a product as it travels on a conveyor line. A printed label is fed onto a pad and held by vacuum; the unit’s 90-degree swing arm then extends to apply the label.

• Browser-based monitoring: The status of all operational functions and configurations can be monitored by logging on to a web page that is unique to each Model 5300 unit.

• Numerous I/O’s: The system can be interfaced with many types of external devices.

• One-to-one media consumption: Special label unwind and rewind dimensions are matched to the system’s ribbon supply to ensure they are consumed at the same rate, reducing downtime and eliminating partial changeovers.

• Print job storage: Multiple label printing formats can be stored in the system’s memory, making it easier for an operator to select a job directly from the applicator instead of downloading a computer file.

The Model 5300 swing tamp system boasts numerous additional features including an upgradeable microprocessor controller, various inputs/outputs, plus durable construction that will withstand harsh industrial environments.

There also are several optional enhancements that can increase the system’s functionality. A product height sensor, for example, enables the printer-applicator to label items of varying heights delivered by the same conveyor.

Other options include a 15-foot umbilical connection that enables the remote location of the unit’s controller; an adjustable stand for optimum system orientation; label-on-pad and product-presence sensors; plus beacon light alerts to signal the status of label and ribbon supplies.

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

5300Zebra FS20 Fixed Industrial Scanner

An Easily Integratable Scanning Solution

The increasing demands of international commerce and its global supply chain are pressuring companies to deliver more — and to do it faster. From manufacturing to logistics to the end customer, success is driven by the ability to quickly move and track the products that drive your business.

Address it all with the compact Zebra FS20 Fixed Industrial Scanner. With the FS20, it’s easy to track and trace every item as it moves through production, storage and fulfilment. Scan barcodes on components moving through your assembly line to ensure the right part is used at the right time — and enable rapid targeted recalls of products that contain defective parts. Scan barcodes on items as they are placed on warehouse shelves to provide visibility into real time inventory. And scan barcodes when fulfilling orders to ensure the right items are sent to the right customer. Whatever you want to track and trace, the FS20 makes it easy.

View ProductMarkoprint Integra PP 108

The Markoprint Integra PP108 is the first inkjet printer with SEIKO printing technology and a circulating ink system. It features a POZIFLOW circulating ink system which prevents the accumulation of air in the nozzles and ensures a permanent, clean print image without missing print due to blocked nozzles. The system’s ink tank can be installed above, below, or at the same height as the print head without any problems. The new SEIKO printhead has a print height of 108 mm and achieves a remarkable speed of up to 150 meters per minute with a high resolution of 360 dpi.

Suited to Dual Colour Printing Applications such as Hazard Labelling, Dual Colour overprinting and Direct Printing Applications to corrugate, and web printing applications, the PP108 is the latest high end, economical Inkjet System using the latest Drop on Demand Printing Technology.

View ProductMarkoprint Integra Ultimate

The innovative Integra Ultimate thermal inkjet printer not only provides IP65 protection against dust and moisture, but it also closes and cleans the nozzle plate at each pause. This system ensures that the printing is always clean, with faultless results even after extended breaks. As a result, the ink cartridges’ open times are multiplied many times. Two HP Class thermal inkjet ink cartridges can be used with the print head. As a result, the system produces beautiful prints with a maximum height of 25 mm.

View ProductMarkoprint Integra Quadro/Quadro²

The new Markoprint Integra Quadro/Quadro² print controller can control up to four inkjet printers or four print positions at the same time. This allows you to print on both sides of primary and secondary packaging on one or two separate production lines. There are also two separate printing methods that can be used in this process.

The Markoprint Integra Quadro/Quadro² can easily cope with limited space thanks to its slender design. Installation inside or directly at the industrial line is straightforward thanks to the different fixation options. It was designed specifically for installation in control panels and machinery.

View Product