Trident

Trident is perfect for text, barcode and graphic marking on absorbent and smooth surfaces.It is easy to use, highly reliable and can reach printing speeds up to 60 meters per minute.

Click on the Direct Sales Button, and contact us today to order your Trident inkjet thermal inks.

- High reliability

Piezo-controlled graphic printing for industry-standard fonts, with almost unlimited number of rows.

- high printing speeds in barcode quality

up to 60 m/minute at 192 dpi (maximum 200 m/minute)

- good print image

based on perfected and proven Piezo technology

- simple operation

through integrated maintenance module

- unique flexibility

through the use of several Trident printheads

- Maximum 50 mm to 800 mm printing heights possible, as well as freely configurable layouts

- Multi-sided coding of packaging on two sides (top, side or at different production lines)

- virtually any porous surfaces can be marked, depending on ink type

- Topping up ink whilst in operation

- up to 5 mm distance from printhead to product surface enables marking of cartons with surface tolerances

- highly economical

- Best price-performance ratio in terms of ratio: cost of ink to area printed

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

PLUSMARK – Premium Wax

PLUSMARK is the high performance wax ribbon from Weber. It offers all

the benefits of a general purpose wax ribbon with an improved print durability

and a capability to print on synthetic label materials.

Markoprint Integra PP 108

The Markoprint Integra PP108 is the first inkjet printer with SEIKO printing technology and a circulating ink system. It features a POZIFLOW circulating ink system which prevents the accumulation of air in the nozzles and ensures a permanent, clean print image without missing print due to blocked nozzles. The system’s ink tank can be installed above, below, or at the same height as the print head without any problems. The new SEIKO printhead has a print height of 108 mm and achieves a remarkable speed of up to 150 meters per minute with a high resolution of 360 dpi.

Suited to Dual Colour Printing Applications such as Hazard Labelling, Dual Colour overprinting and Direct Printing Applications to corrugate, and web printing applications, the PP108 is the latest high end, economical Inkjet System using the latest Drop on Demand Printing Technology.

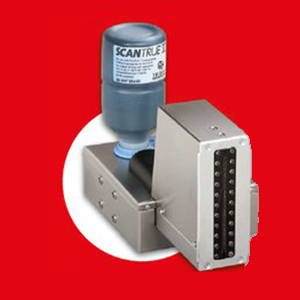

View ProductMarkoprint Integra Quadro/Quadro²

The new Markoprint Integra Quadro/Quadro² print controller can control up to four inkjet printers or four print positions at the same time. This allows you to print on both sides of primary and secondary packaging on one or two separate production lines. There are also two separate printing methods that can be used in this process.

The Markoprint Integra Quadro/Quadro² can easily cope with limited space thanks to its slender design. Installation inside or directly at the industrial line is straightforward thanks to the different fixation options. It was designed specifically for installation in control panels and machinery.

View ProductULTRAPRINT – High durability resin

ULTRAPLATE is the standard resin ribbon from Weber. It is dedicated to

applications requiring a perfect printing quality and excellent mechanical

resistances. Its high versatility (it also prints on coated papers) and its

performances (sharpness, printing speed) have resulted in making

ULTRAPLATE a market reference.