Weber 121 Wrap-Around Label Applicator

Weber’s versatile 121 provides a simple, cost-effective solution to low-volume wrap-around labelling that is as accurate and flexible as similar labelling systems used in larger-scale operations. This labelling system features the fast and accurate positioning of full, overlap and partial-wraps of pressure-sensitive labels on cylindrical containers.

Products up to 7″ in diameter and up to 12″ high easily can be accommodated using the system’s adjustable guide rails. It can handle labels up to 6 inches tall and 12 inches long and apply them at rates up to 45 products per minute to a variety of sized products. During application, labels are peeled away from the liner and securely attached to products using the wipe-on label applicator and a wrap station.

The brand-new Weber 121 system features a cost-efficient Alpha Compact labelling system mated with a wrap conveyor for a compact, easy-to-use solution for labelling bottles and other round straight-walled products. This heavy-duty wrap-labeller can be inserted into your production line to give you consistent end-to-end labelling and better control over your production.

Applies label up to 6″ high x 12″ long

Stand-alone or add to a production line

Placement accuracy of 0.03″

If you are looking for a reliable, economical bottle-wrap labelling system that is easy to set up and simple to maintain then check out the Weber 121. Industries that use the Model 121:

Craft beer labelling

Medical and pharmaceutical container labelling

Food/Sauce bottle labelling

Cylindrical beverage & juice bottle labelling

Products are delivered to the Weber 121’s built-in Alpha Compact applicator head via a 7.75″-wide, 45″-long belt conveyor, which permits product transfers at both the entry and discharge ends. The unit is capable of a superb placement accuracy of 0.03″. The Weber 121 can be integrated into existing production processes or operate as a manually fed, stand-alone solution. The unit also boasts robust steel construction that makes it ideal for lower-volume, intermittent labelling projects or for multiple-shift operations.

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

Geset 121 Instructions ManualGeset 121 Computer Assisted Design

EASYMARK – Standard Wax

EASYMARK is the standard Weber wax ribbon which delivers consistent print

quality on any kind of paper label materials. It prints high density legible

barcodes and traceability data for short life labeling needs.

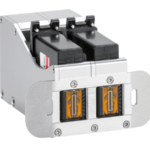

Markoprint NonStop Printing

To enable continuous marking in ongoing production, our Markoprint NonStopPrinting printhead holds two alternately printing cartridges. Because the other ink cartridge is printing on the same position, each ink cartridge can be changed, cleaned, or serviced without pausing the machine.

An intelligent automatism prevents both cartridges from going empty at the same time. The first cartridge will always print two consecutive print jobs, taking turns with the second cartridge, which will only print one. This sophisticated automatism avoids both cartridges from running out at the same time. This will keep the ink from drying out in both cartridges. When the cartridge with the larger print volumes is empty, a warning will show, and the other cartridge will continue printing until it is replaced. The new cartridge will print the lower quantities to allow for you to replace the “older” cartridge. A sophisticated workflow that will boost your efficiency and productivity.

View ProductULTRAPRINT – High durability resin

ULTRAPLATE is the standard resin ribbon from Weber. It is dedicated to

applications requiring a perfect printing quality and excellent mechanical

resistances. Its high versatility (it also prints on coated papers) and its

performances (sharpness, printing speed) have resulted in making

ULTRAPLATE a market reference.

Geset 117 Top and Bottom Labelling System

The Geset 117 labelling system is used to label square products on the top and bottom side automatically. Depending on the type and dimension of the product, different label sizes are used. The products are fed manually or by a conveying system provided by the customer at an infeed passage on the labelling system. Care should be taken on accurate alignment of the products. It is essential that the products are forwarded separately to the applicator with a gap between each other.

When the light barrier is reached, an application trigger is tripped. Both label applicators apply then in Wipe On procedure a label onto the product. The label on top side is pushed on the product by a brush or roller. The label on bottom side is pushed on the product by the self-weight of the product. After labelling the products move on and can be removed from conveyor by the customer.

View Product